November. I’m driving south on 5 near Sea World Dr. during the afternoon rush hour. Happy as can be, not a care in the world except the itch on my arm from the flu shot I just endured. Then I realize my ’59 Apache is making a strange noise.

- Then a sound like I dropped a still running drill on the floor. Wirrrrrrrrrrrrrrrrrrrr.

Forward momentum stops and it’s time to get over to the shoulder – fast. I figured I messed up my transmission. No worries, I have a spare on the floor in the garage. AAA hooks me up with a tow to Car Connection in Barrio Logan.

It’s not the transmission, the engine is seized. The pickup had been running so well, too. I had just had the head, carb and distributer rebuilt. Oh, well.

The fix was to have the bottom of the motor rebuilt. I picked up a good rebuilder 235 from my buddy Mark at work and the guys at Car Connection sent it to the machine shop. Thankfully I was able to borrow a vehicle from work to drive.

A couple days later I had Louie (from Car Connection) stop by my house and look at my 1952 Styleline Deluxe. There was a list of small things a page long that needed to be finished before it was roadworthy and I was tired of looking at it in the garage. Louie gave me a price of around $700 to get the list knocked out. I figured that I might as well get both the sedan and the pickup on the road, so the ‘52 Styleline was on a tow truck to Car Connection as well.

The list:

Finish the under-dash wiring, figure out the throttle assembly, reseat the coil spring on the drivers side, install a transmission dipstick, setup the kickdown cable for the transmission, fill the car with fluids, put hoses on the radiator and 10 or 15 other little things.

This is where the fun starts.

In the space of 3 weeks (including the down time due to December madness) they had everything ready to rock – at least that’s what we thought. The 52 was ready to fire!

At least it was ready until Louie’s dad asked the question “Have you hooked up all the cables for the 700r4?” It turns out (unknown to Louie and me) that the 700r4 has what is called a Throttle Valve cable that attaches to the throttle assembly. It has to move at pretty much precisely the same amount as the throttle. With all the custom stuff attached to my carbs, there was no way to get the TV cable setup… and the 700r4 was not the right transmission for a 250 inline 6 anyways.

The search was on for a TH350 transmission. It was going to cost less than working out the crazy geometry of the throttle, the kickdown and the TV cable all attached to a custom throttle rod.

The sky opened up and the angry god of thunder sent more rain on San Diego that has been seen in years. Buckets. My neighbor started building an ark.

Craigslist was a bust for a TH350, so we were relying on getting one from a source that Car Connection had had success with in the past. The only problem was that his wrecking yard was not paved and all the rain had turned it into soup. Two weeks of waiting.

We finally got lucky. They had a good transmission and it was a perfect match sizewise for the 700r4 that was being pulled… even better, they guy was willing to take that 700 in trade! The fresh TH350 was in and bolted up, the dipstick tube, the kickdown and the throttle had been figured out and it was time to turn the key.

FAIL.

It's so disheartening when I roll over the list of parts that failed in my mind:

The cool Mallory dual points distributer was bad – it was replaced with a stock one.

The fuel pump was thought to be bad, so we replaced it. The next one was bad, too. It turns out that the cam lobe that drives the fuel pump was the problem. Electric fuel pump swapped in (clack-clack-clack-clack).

The rear carburetor had a bad seat, so as it idled it would flood. The guys I got the motor from sent me the parts to correct the problem.

The stock intake that was milled to accept the 2 glassbowl Holley carbs was not correctly engineered. Only cylinder 1 and 6 were getting any fuel. Also, the carb mounting points were not right. There simply was not enough meat to properly seal the carb to the intake, air was getting in. Also, it had a vacuum leak.

The throttle assembly was bolted into the head where the valve cover bolts were supposed to be. At the top of each bolt was a heim joint that the rod went through. If you properly tightened the bolts so that the valve cover would not leak, the throttle rod would bind and not actuate.

The chrome aftermarket valve cover was hitting one of the rockers. I was lucky enough to have a stock one laying around the garage.

The re-cored radiator leaks.

The starter was bad, Carquest replaced it without a problem.

The motor mounts were set up so that there was no give. Might as well have just welded that 250 to the frame. The whole car vibrates badly when it’s on.

The solution to the intake – carb – throttle problem was to abandon that entire setup, find a stock intake and buy a 2bbl Holley carb and an adapter to run it. Goodbye killer looking glass-bowl Holleys. Even this solution was not without hangups. The first 2bbl I received was bad, but I was promptly shipped another one and it’s a runner.

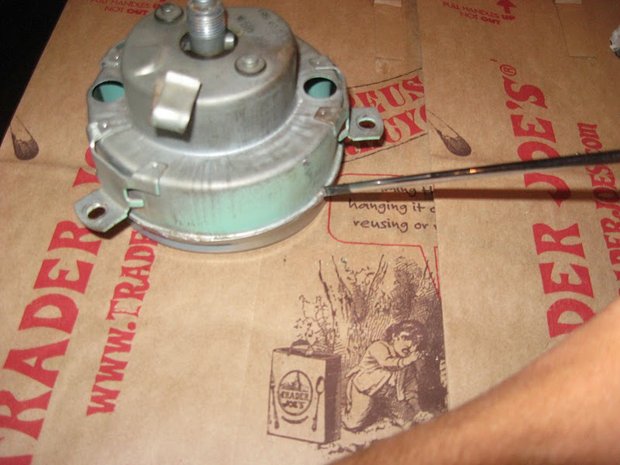

The real kicker was that the rear main seal had failed and the damned thing was leaking a lot of oil. On pulling the oil pan we discovered that the inside of the block was full of metal bits and the crank bearings were all gouged up.

.JPG)

The original $700 that this job was supposed to cost ballooned to over $3000. Because of all the trial and error, many of the tasks had to be done twice if not 3 times.

My beautiful 1952 Styleline Deluxe 2 door sedan runs… for 15 minutes. Then the oil pressure drops to doughnut and needs to be turned off. I got this dressed up 250 L6 as half of the purchase price when I sold my ’63 Plymouth Valiant. Turns out it was just a glossy black and finned aluminum anchor. I really don’t fault the guys that I got it from. The real pain point is that they did not run it before they sent it. All the issues would have become evident and resolved.

More time, more money. I’m going to have to find another 250 to have rebuilt. I also still don’t have my Apache back. There was a problem finding a cam for that 235. The motor is back together now and I should have it on the road soon, no drama with this build.

One bright note. I got to drive it. Its been a year and a half since I last cruised around in my car. Henry helped me wash it and I even took the wife to dinner! (short trips). Fuck I love that car.

Paint and chrome won't get you home.

.JPG)